A speed square is an indispensable tool in carpentry and construction, known for its versatility in measuring, marking, and ensuring precise angles. This review delves into the performance and reliability of speed squares, examining their key features, accuracy, and overall effectiveness to help users determine which model best suits their needs.

1. Accuracy and Precision

Angle Measurement: Speed squares are designed to provide accurate angle measurements, typically featuring markings for 90°, 45°, and 30° angles. Their ability to deliver consistent angles is crucial for tasks like framing, roofing, and layout work. Precision in these measurements directly impacts the quality of the finished work.

Graduation Marks: Many speed squares come with detailed graduation marks along their edges, allowing for precise measurement of distances and angles. These markings are usually etched or stamped into the metal, ensuring they are clear and durable over time.

Consistency in Performance: Evaluating the accuracy of a speed square involves checking its ability to consistently provide correct measurements. Reliable speed squares will align with other measurement tools and deliver repeatable results, which is vital for maintaining quality and consistency in carpentry projects.

2. Build Quality and Durability

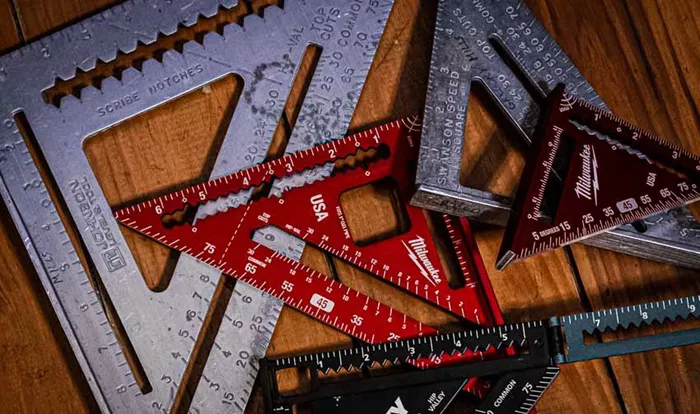

Material Construction: Speed squares are commonly made from aluminum, steel, or plastic. Aluminum and steel models are known for their durability and resistance to bending or warping, while plastic models may offer lighter weight and affordability. The choice of material affects the tool’s longevity and its ability to maintain accuracy under various conditions.

Build Quality: The overall build quality of a speed square includes the sturdiness of the edges, the clarity of the markings, and the precision of the angle cuts. A well-constructed speed square will have clean, straight edges and clearly defined markings that resist wear and tear.

Wear Resistance: Over time, a speed square may experience wear from frequent use. Models with hardened surfaces or protective coatings are less likely to show signs of wear, ensuring long-term reliability and accuracy.

3. Ease of Use

User-Friendly Design: A good speed square should be easy to handle and operate. Features like a comfortable grip, lightweight design, and clear markings contribute to a user-friendly experience. Some models include additional features like a built-in ruler or protractor, enhancing their functionality.

Visibility of Markings: The visibility of the measurement markings is crucial for ease of use. High-contrast markings, large font sizes, and clear graduations improve readability and reduce the chances of measurement errors.

Versatility: The versatility of a speed square includes its ability to serve multiple functions, such as marking angles, checking squareness, and measuring distances. A reliable speed square should offer a range of applications, making it a versatile tool for various tasks.

See also: How Far Apart Should Studs Be For Optimal Support?

4. Accuracy Testing and Calibration

Checking Against Standards: To evaluate a speed square’s accuracy, it’s essential to test it against known standards or calibration tools. Comparing the speed square’s measurements with those of a verified reference tool can confirm its precision and reliability.

Calibration Methods: Some speed squares may require periodic calibration to ensure ongoing accuracy. Understanding how to calibrate the tool, if necessary, helps maintain its performance and reliability over time.

5. Brand and Model Comparisons

Reputable Brands: Established brands in the industry, such as Stanley, Irwin, and Johnson, are known for their high-quality speed squares. Comparing different brands can help identify which offers the best combination of accuracy, durability, and ease of use.

Model-Specific Features: Different models may offer varying features, such as integrated rulers, built-in level vials, or digital readouts. Evaluating these features helps determine which model best meets specific needs and preferences.

6. User Feedback and Reviews

Expert Opinions: Reviews from carpenters, builders, and other professionals provide valuable insights into the performance and reliability of speed squares. Expert opinions can highlight the strengths and weaknesses of different models based on real-world use.

Customer Reviews: User feedback from consumers who have used the speed square for various projects offers practical insights into its performance. Positive reviews often indicate a tool’s reliability and accuracy, while negative reviews may reveal potential issues.

Common Issues: Common issues reported by users include difficulties with reading measurements, inaccuracies over time, or problems with the tool’s construction. Addressing these issues in the evaluation helps identify models that offer better long-term performance.

7. Value for Money

Cost vs. Performance: Evaluating the cost of a speed square in relation to its performance and features is essential for determining its value for money. Higher-priced models may offer enhanced accuracy or durability, while budget-friendly options might provide adequate performance for occasional use.

Long-Term Investment: A speed square is a tool that should provide reliable performance over many years. Investing in a high-quality model may offer better long-term value compared to cheaper alternatives that may require frequent replacement or calibration.

Conclusion

A reliable speed square is characterized by its accuracy, durability, ease of use, and versatility. Evaluating these aspects helps determine which speed square will best meet your needs, whether for professional construction tasks or DIY projects. By considering factors such as build quality, user feedback, and value for money, you can make an informed decision and choose a speed square that will provide dependable performance and precision for years to come.

Related Topics: