Hacksaws are essential hand tools used for cutting various materials, with metal being a common target. Over time, different types of hacksaws have been developed to meet specific cutting needs, each with its own unique features, advantages, and applications. In this article, we will explore the three main types of hacksaws: the traditional adjustable – frame hacksaw, the fixed – frame hacksaw, and the compound – action hacksaw.

Traditional Adjustable – Frame Hacksaw

Design and Structure

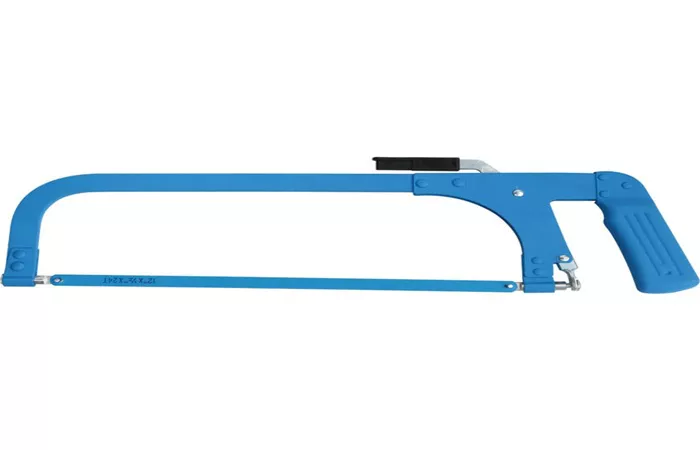

The traditional adjustable – frame hacksaw is perhaps the most well – known and widely used type. Its frame is the key feature that sets it apart. The frame is made of durable materials, typically steel or aluminum, which provide the necessary strength and rigidity to hold the blade under tension during cutting operations.

The frame consists of two main parts: a fixed end and an adjustable end. The fixed end is where one side of the blade is attached, usually via a pin or a quick – release mechanism. The adjustable end, on the other hand, allows the user to change the length of the blade that can be installed. This is achieved through a screw – type adjustment mechanism. By turning the adjustment screw, the user can either extend or retract the adjustable end, thereby accommodating different blade lengths. This adjustability is a significant advantage as it enables the use of various blade sizes, depending on the thickness and type of material to be cut.

The handle of the adjustable – frame hacksaw is designed for user comfort and control. It is usually made of materials such as plastic, rubber, or wood. Plastic and rubber handles are popular because they offer a good grip, even in wet or slippery conditions. They also provide some shock absorption, reducing the vibration that is transmitted from the blade to the user’s hand during cutting. The shape of the handle is often ergonomic, fitting the natural contour of the hand to minimize fatigue during extended use.

Blade and Cutting Characteristics

The blades used in adjustable – frame hacksaws are typically thin, flexible strips of metal with teeth along one edge. These blades are available in different materials, including high – carbon steel, high – speed steel (HSS), and bi – metal. High – carbon steel blades are relatively inexpensive and are suitable for general – purpose cutting of soft metals and plastics. However, they tend to dull more quickly when cutting harder materials.

High – speed steel blades, on the other hand, are more durable and can cut through harder metals such as stainless steel and tool steel. They maintain their sharpness for a longer time, making them a better choice for heavy – duty cutting tasks. Bi – metal blades combine the benefits of both high – speed steel and a more flexible backer metal. The high – speed steel cutting edge provides excellent cutting performance, while the flexible backer allows the blade to withstand the stresses of cutting without breaking easily.

The number of teeth per inch (TPI) on the blade determines its cutting characteristics. Blades with a lower TPI, such as 14 or 18 TPI, have larger teeth and are better for cutting thicker materials. They can remove material more quickly but may leave a rougher cut surface. Blades with a higher TPI, such as 24 or 32 TPI, have smaller teeth and are suitable for cutting thinner materials or for making more precise cuts. They produce a smoother finish but cut at a slower pace.

Applications

The adjustable – frame hacksaw is a versatile tool with a wide range of applications. In metalworking, it is commonly used to cut metal bars, rods, and pipes to the desired length. For example, in a plumbing project, it can be used to cut metal pipes to fit the specific requirements of the installation. In automotive repair, it can be used to cut through bolts, nuts, and other metal parts that are damaged or need to be removed.

It is also useful in DIY and home improvement projects. Whether it’s cutting a piece of metal for a homemade shelf, trimming a metal bracket for a furniture repair, or making a small modification to a metal fixture, the adjustable – frame hacksaw can handle the task. Its ability to adjust the blade length makes it suitable for different cutting needs, from small, detailed cuts to longer, more extensive cuts.

Fixed – Frame Hacksaw

Design and Structure

The fixed – frame hacksaw has a simpler design compared to the adjustable – frame model. As the name suggests, its frame is fixed in length and does not have an adjustable mechanism. The frame is usually made of a single piece of metal, such as steel, which provides a rigid and stable structure for holding the blade.

The handle of the fixed – frame hacksaw is attached directly to the frame. Similar to the adjustable – frame hacksaw, the handle is designed for comfort and control. It is often made of materials like plastic or rubber to offer a good grip and reduce vibration during use. The fixed – frame design gives the tool a more compact and lightweight feel, which can be an advantage in certain situations.

Blade and Cutting Characteristics

Fixed – frame hacksaws use blades that are similar in design to those used in adjustable – frame hacksaws. They are available in various materials, including high – carbon steel, high – speed steel, and bi – metal, and come in different TPI options. However, since the frame is fixed, only blades of a specific length can be used. This means that the user has less flexibility in terms of blade selection compared to the adjustable – frame model.

The cutting action of a fixed – frame hacksaw is the same as that of an adjustable – frame hacksaw. The blade cuts on the forward stroke, and the user applies pressure to remove material from the workpiece. The fixed – frame structure provides a stable platform for the blade, which can result in more consistent cuts, especially when cutting smaller or thinner materials.

Applications

Fixed – frame hacksaws are well – suited for tasks that require a more compact and lightweight cutting tool. They are often used in situations where space is limited, such as in tight mechanical enclosures or when working in confined areas. For example, in electronics repair, where small metal components may need to be cut, a fixed – frame hacksaw can be a convenient option.

They are also popular among hobbyists and model – makers. When cutting small pieces of metal for model airplanes, ships, or other miniature projects, the fixed – frame hacksaw’s simplicity and compact size make it easy to handle and control. Additionally, for light – duty metal – cutting tasks around the house, such as trimming a small piece of metal for a craft project, a fixed – frame hacksaw can get the job done effectively.

Compound – Action Hacksaw

Design and Structure

The compound – action hacksaw is a more advanced type of hacksaw that incorporates a unique design feature. In addition to the traditional forward – cutting motion, the compound – action hacksaw has a mechanism that allows the blade to move in an arc during the forward stroke. This arc – like motion is achieved through a pivoting frame or a linkage system.

The frame of the compound – action hacksaw is usually made of high – strength metal, such as steel or aluminum, to withstand the stresses of the compound – cutting action. The handle is designed to provide a comfortable grip and good control over the tool. Some models may have additional features, such as a blade – tensioning indicator or an ergonomic handle design, to enhance the user experience.

Blade and Cutting Characteristics

The blades used in compound – action hacksaws are similar to those used in other types of hacksaws. However, due to the unique cutting motion, the blades may need to be more flexible and durable to withstand the additional forces applied during the arc – like movement.

The compound – cutting action of the hacksaw offers several advantages in terms of cutting performance. The arc – like motion of the blade allows it to cut more efficiently by increasing the contact area between the blade and the material being cut. This results in faster cutting speeds and less effort required from the user. Additionally, the compound – action design can help to reduce the strain on the blade, potentially extending its lifespan.

Applications

Compound – action hacksaws are particularly useful for cutting thick or tough materials. In industrial settings, where large – diameter metal pipes or thick metal bars need to be cut, the compound – action hacksaw can make the task much easier and faster compared to traditional hacksaws.

They are also used in metal fabrication shops for cutting various metal components. The increased cutting efficiency and reduced user effort make the compound – action hacksaw a preferred choice for professionals who need to make a large number of cuts or work with challenging materials. In some DIY projects where cutting through thick metal is required, such as building a metal – framed structure, a compound – action hacksaw can be a valuable addition to the toolbox.

Conclusion

The three types of hacksaws – the traditional adjustable – frame hacksaw, the fixed – frame hacksaw, and the compound – action hacksaw – each have their own distinct features, cutting characteristics, and applications. Understanding these differences can help users choose the right type of hacksaw for their specific cutting tasks, whether it’s a simple DIY project at home or a complex industrial cutting operation.

Relevant topics: