When it comes to woodworking, choosing the right type of nail is crucial for the success of your project. Brad nails and finish nails are two popular options, each with its own characteristics, advantages, and disadvantages. Understanding these differences is essential for selecting the right fastener for your specific needs. In this article, we will delve into the features, applications, and price-performance ratios of both brad nails and finish nails to help you make an informed decision.

Understanding Brad Nails

What Are Brad Nails?

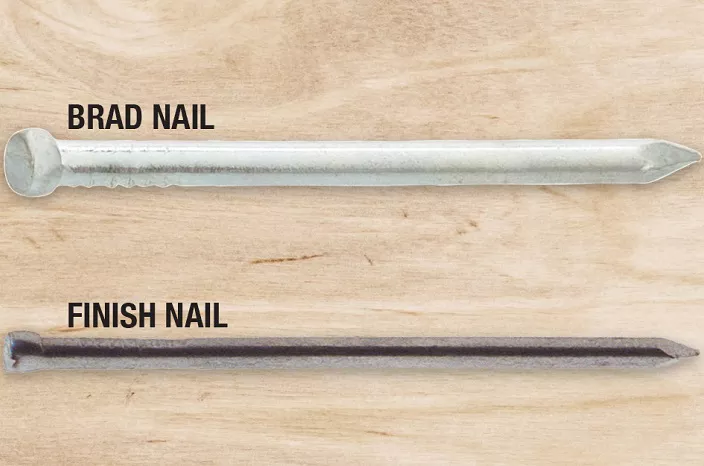

Brad nails are thin, lightweight nails typically ranging from 18-gauge to 23-gauge in thickness. They are usually made from steel and are designed for use in a variety of light-duty applications. The size of brad nails usually ranges from ½ inch to 2 inches in length, making them ideal for delicate projects.

Characteristics of Brad Nails

Size and Gauge: The gauge of brad nails indicates their thickness, with higher numbers indicating thinner nails. 18-gauge brad nails are commonly used for most applications, while 23-gauge brads are even thinner and primarily used for very light applications.

Head Design: Brad nails have a small head that is often barely visible once driven into the material. This allows for a clean finish, as the nail can be countersunk and filled with wood filler if needed.

Holding Power: While brad nails provide adequate holding power for lightweight materials, they may not be suitable for heavy-duty applications or for materials that experience stress.

Applications of Brad Nails

Brad nails are commonly used for:

Trim Work: Ideal for attaching lightweight trim and moldings due to their small size and discreet appearance.

Crafts and Hobby Projects: Suitable for projects where precision and a neat finish are essential.

Furniture Assembly: Effective for lightweight furniture and frames, especially when using softer woods.

Advantages of Brad Nails

Ease of Use: Brad nailers are lightweight and easy to handle, making them user-friendly for beginners and professionals alike.

Minimal Splitting: The thin gauge reduces the risk of splitting the material, especially in delicate woods.

Quick Application: Brad nails can be driven in quickly, making them efficient for larger projects.

Disadvantages of Brad Nails

Limited Strength: Not suitable for applications requiring heavy-duty fastening or structural integrity.

Not Ideal for Dense Materials: May not hold well in hardwoods or dense materials due to their thin gauge.

Understanding Finish Nails

What Are Finish Nails?

Finish nails, typically ranging from 16-gauge to 18-gauge, are thicker than brad nails and designed for more robust applications. They come in lengths from 1 inch to 3.5 inches, allowing for greater versatility in construction and woodworking projects.

Characteristics of Finish Nails

Size and Gauge: Finish nails are thicker than brad nails, providing greater holding power. The 16-gauge finish nails are often preferred for more substantial applications.

Head Design: Finish nails have a larger, flat head compared to brad nails. This design allows them to be countersunk more easily and provides a stronger surface for finishing.

Holding Power: Due to their thicker gauge, finish nails offer superior holding power, making them suitable for a wider range of applications.

Applications of Finish Nails

Finish nails are commonly used for:

Crown Molding: Ideal for securing crown molding, which often requires strong fasteners due to its weight.

Door and Window Casings: Excellent for framing around doors and windows where durability is crucial.

Cabinetry: Suitable for constructing cabinets and furniture that need added structural integrity.

Advantages of Finish Nails

Strong Holding Power: Their thicker gauge provides greater strength, making them ideal for more substantial applications.

Versatility: Finish nails can be used in various materials, including hardwoods, without compromising holding power.

Better for Heavy Applications: Suitable for tasks that require additional strength and durability.

Disadvantages of Finish Nails

Potential for Splitting: Their thickness can lead to splitting in delicate materials, requiring more care during installation.

More Visible: The larger head is more noticeable, which may require additional finishing work to achieve a clean appearance.

Price-Performance Ratio

When evaluating brad nails and finish nails, it’s essential to consider their price-performance ratio based on your specific needs.

Cost Comparison

Brad Nails: Typically less expensive than finish nails due to their thinner gauge and lighter applications. A box of 1,000 brad nails may range from $10 to $20, depending on the gauge and brand.

Finish Nails: Generally cost more because of their thicker gauge and increased holding power. A box of 1,000 finish nails usually costs between $15 to $30.

Performance Considerations

Project Requirements: If you’re working on light-duty projects like trim work or crafts, brad nails offer a better price-performance ratio. However, for heavier projects, finish nails provide the strength needed, justifying the higher cost.

Durability Needs: Consider the longevity and durability of your project. For items that will bear weight or require stability, investing in finish nails will likely result in a better long-term outcome.

Choosing Between Brad Nails and Finish Nails

When to Use Brad Nails

Lightweight Projects: Opt for brad nails when working with lightweight materials or projects that do not require high holding power.

Detailed Finishing: Choose brad nails for projects where aesthetics are essential, as they leave smaller holes that are easier to fill and finish.

When to Use Finish Nails

Heavy-Duty Applications: Use finish nails for projects requiring strong fastening, such as crown molding, cabinetry, or any structural elements.

Increased Holding Power: If your project involves denser materials or will be subjected to stress, finish nails are the better option.

Conclusion

Both brad nails and finish nails serve unique purposes in woodworking and construction. Brad nails excel in applications requiring a delicate touch and a clean finish, making them ideal for trim work and crafts. On the other hand, finish nails offer greater holding power, making them suitable for more robust applications.

In evaluating which fastener to use, consider the specifics of your project, including the materials involved and the desired outcome. Assess the price-performance ratio in relation to your project needs to make an informed decision. By understanding the strengths and weaknesses of each type of nail, you can ensure the success of your woodworking endeavors, ultimately achieving a professional and lasting finish.

Related topics:

- Milwaukee Dolly Cart: Comprehensive Review And Analysis

- Pittsburgh 3 Ton Floor Jack: A Comprehensive Tool Evaluation

- A Comprehensive Evaluation Of Hand Sanders