Nail guns are powerful tools that drive nails into various materials. These devices revolutionized construction by replacing manual hammers. Professionals and DIY enthusiasts use them for efficiency and precision. Different models suit specific applications.

The basic mechanism involves compressed air, electricity, or combustion to propel nails. Each type has unique advantages. Choosing the right nail gun requires understanding these differences. This knowledge ensures optimal performance and safety.

Power Source Variations

Pneumatic nail guns remain the most common type. They use compressed air from an external tank. These models offer consistent power for heavy-duty tasks. Contractors favor them for framing and roofing jobs.

Cordless electric nail guns provide excellent mobility. Battery-powered versions eliminate hose restrictions. They’re ideal for remote locations without air compressors. However, they may lack power for dense materials.

Gas-powered nail guns combine combustion and batteries. They’re completely portable like cordless models. These excel in outdoor applications. The combustion mechanism delivers strong driving force.

Nail Size and Type Compatibility

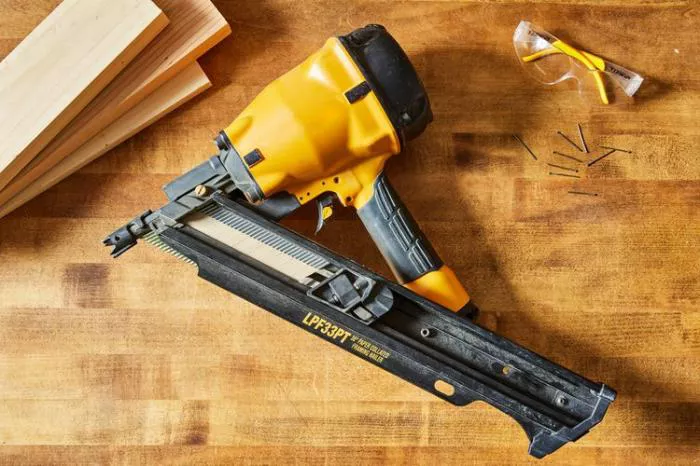

Framing nailers handle large nails from 2 to 3.5 inches. They construct wooden frames for houses. The heavy-duty design withstands constant use. These typically use clipped or round head nails.

Finish nailers work with smaller 15 or 16 gauge nails. They attach trim and molding without visible holes. The angled magazine improves accessibility. These create professional-looking results.

Brad nailers use even thinner 18 gauge nails. They’re perfect for delicate woodworking projects. The tiny nails minimize material damage. Cabinet makers frequently use this type.

Magazine Design Differences

Strip magazines hold nails glued together in strips. They typically accommodate more fasteners. The design suits high-volume nailing tasks. Roofing nailers often use this configuration.

Coil magazines contain nails wound in a circular arrangement. They hold significantly more nails than strip types. This reduces reloading frequency during large projects. Framing nailers commonly feature coil magazines.

Firing Mechanism Options

Sequential trigger systems require two actions. The user must press the nose then pull the trigger. This safety feature prevents accidental discharges. It’s ideal for precision work.

Contact trip mechanisms allow rapid firing. Simply holding the trigger and bumping the nose drives nails. This increases speed for production work. However, it raises accident risks.

Specialized Nail Gun Types

Roofing nailers have wide heads for asphalt shingles. They typically use coil magazines. The design prevents material damage. Some models include depth adjustment features.

Siding nailers accommodate specific nail types. They prevent cracking of vinyl or fiber cement. The specialized design ensures proper fastener penetration. Many include adjustable guides.

Flooring nailers install hardwood floors efficiently. They drive nails at precise angles. The design prevents surface damage. Some models require mallet strikes for activation.

Safety Features Comparison

Depth adjustment controls are crucial. They prevent over-driving or under-driving nails. This feature appears on most professional models. It ensures consistent results across materials.

No-mar tips protect workpiece surfaces. These rubber or plastic attachments prevent scratches. Finish nailers often include this feature. It’s essential for visible surfaces.

Anti-dry fire mechanisms prevent empty operation. They stop firing when nails run low. This protects the tool from damage. Many modern nail guns incorporate this technology.

Application-Specific Considerations

Construction sites demand durable pneumatic models. The consistent power handles dense lumber. Weather conditions rarely affect performance. Interchangeable nails suit various tasks.

Woodworking shops benefit from precision brad nailers. The smaller fasteners leave minimal marks. Delicate materials require this finesse. Multiple gauge options increase versatility.

Home improvement projects often use cordless models. The convenience outweighs slight power reductions. Battery life suffices for most DIY tasks. No compressor means easier storage.

Maintenance Requirements

Pneumatic nail guns need regular lubrication. Air tool oil maintains internal components. Moisture traps prevent tank corrosion. Daily checks ensure optimal performance.

Cordless models require battery care. Proper charging extends battery life. Clean contacts improve power transfer. Storage in moderate temperatures preserves capacity.

All types benefit from regular cleaning. Sawdust and debris affect functionality. Manufacturer guidelines specify maintenance schedules. Professional servicing may be necessary annually.

Cost and Value Analysis

Pneumatic models offer the best value for professionals. Lower initial cost and durability justify investment. Compressor requirements add to expenses. Long-term reliability offsets this.

Cordless nail guns command premium prices. Battery technology increases costs. The convenience justifies expense for many users. Performance continues improving with new models.

Gas-powered units fall between these categories. They eliminate compressors but need fuel cells. The hybrid design provides unique advantages. Outdoor workers find them indispensable.

Environmental Impact Factors

Pneumatic tools have minimal emissions. Compressors may use considerable electricity. Proper maintenance reduces energy waste. Air leaks decrease efficiency significantly.

Cordless models improved with lithium-ion batteries. Older nickel-cadmium types posed disposal challenges. Modern versions offer better sustainability. Recycling programs address battery concerns.

Combustion nail guns produce emissions. The small gas cartridges limit environmental impact. Proper disposal remains important. Manufacturers continue developing cleaner options.

Technological Advancements

Brushless motors enhanced cordless performance. They extend battery life substantially. Heat reduction improves reliability. These innovations narrowed the power gap.

Smart features emerged in premium models. LED lights illuminate work areas. Digital controls adjust driving force precisely. Some connect to mobile apps for monitoring.

Safety systems became more sophisticated. Sequential triggers gained popularity. Jam clearing mechanisms improved. These developments reduced workplace injuries.

User Experience Differences

Weight distribution affects fatigue. Pneumatic models balance well despite hoses. Cordless designs continue improving ergonomics. Extended use tests comfort features.

Noise levels vary significantly. Pneumatic types produce loud reports. Cordless models operate more quietly. Hearing protection remains essential regardless.

Vibration characteristics influence control. Anti-vibration technology minimizes hand strain. This is particularly important for high-volume users. Reduced vibration improves accuracy.

Industry-Specific Preferences

Home builders typically choose pneumatic framing nailers. The power and reliability meet demanding schedules. Coil magazines suit production environments. Durability withstands job site conditions.

Cabinet makers prefer precision brad nailers. The fine fasteners preserve material integrity. Angled magazines access tight spaces. Lightweight designs enhance control.

Roofing contractors need specialized nail guns. The coil capacity handles rapid shingle installation. Ergonomic designs accommodate awkward positions. Weather resistance ensures consistent performance.

Making the Right Choice

Assess your primary applications first. Frequency of use determines durability needs. Material types dictate nail size requirements. Workspace conditions influence power source selection.

Consider your budget realistically. Factor in accessory costs where applicable. Balance initial investment against long-term value. Quality tools often prove cheaper over time.

Test different models when possible. Ergonomics vary between manufacturers. Weight distribution affects user comfort. Trigger preferences are highly personal.

Conclusion

Nail gun differences span power sources to safety features. Understanding these variations ensures proper tool selection. Matching the tool to the task improves results and safety. Technological advancements continue expanding possibilities. Knowledgeable users make the most of these powerful tools.

Relate topics:

- 4 Best Nail Guns for Roofing

- The Ultimate Guide to Choosing the Best Small Nail Gun

- Bosch Finish Nail Gun Review: Is It Worth the Investment?