Tapcon screws are an excellent choice for securing materials to concrete, brick, or block. Their unique design and blue coating provide superior holding power and resistance to corrosion, making them a favorite among professionals and DIY enthusiasts. However, selecting the right Tapcon screws for your project can be daunting due to the variety of sizes and types available. This guide will help you choose the right Tapcon screws for your specific needs.

1. Understanding Tapcon Screws

What Are Tapcon Screw

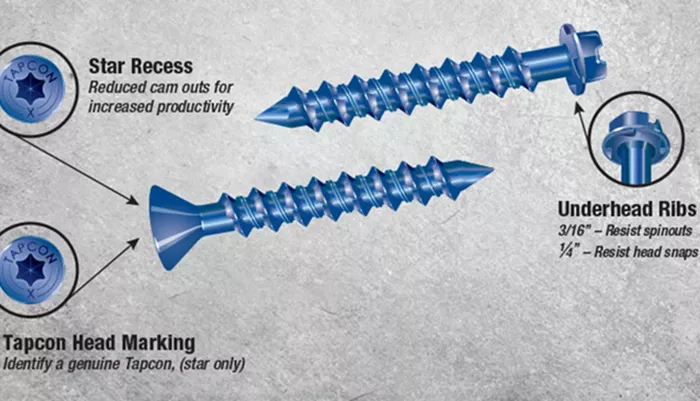

Tapcon screws, also known as masonry screws, are specially designed for anchoring objects to concrete and masonry surfaces. They feature a unique thread design that taps threads into the material as the screw is installed, providing a secure and lasting hold.

Benefits of Tapcon Screws

High Holding Power: The unique thread design ensures a strong grip in masonry materials.

Corrosion Resistance: The blue Climaseal® coating provides excellent protection against rust and corrosion.

Ease of Use: Tapcon screws can be installed with a standard drill, eliminating the need for specialized tools.

Versatility: Available in various sizes and types to accommodate different materials and thicknesses.

2. Choosing the Right Size

Diameter and Length

Tapcon screws come in different diameters and lengths to suit various applications. Selecting the appropriate size is crucial for ensuring a secure hold.

Diameter: Common diameters are 3/16 inch and 1/4 inch. The choice depends on the weight of the object being anchored and the load it will bear. For lighter loads, a 3/16-inch screw is usually sufficient. For heavier loads, a 1/4-inch screw is recommended.

Length: The length of the screw should be at least 1 inch longer than the thickness of the material being anchored. This ensures that the screw penetrates deep enough into the masonry to provide a secure hold. Tapcon screws are available in lengths ranging from 1 1/4 inches to 6 inches.

Application Considerations

Concrete Thickness: Ensure the screw length is appropriate for the thickness of the concrete. For example, for a 2-inch thick piece of material, you would need a screw at least 3 inches long.

Embedment Depth: Tapcon recommends a minimum embedment depth of 1 inch for optimal holding power. However, deeper embedment may be required for heavier loads.

See also: How To Unscrew A Screw Smoothly?

3. Selecting the Right Type

Head Styles

Tapcon screws are available in different head styles, each suited for specific applications.

Flat Head: Ideal for applications where the screw head needs to be flush with the surface of the material. Commonly used in applications like securing wood or metal to concrete.

Hex Head: Provides a larger bearing surface for increased holding power and is easier to drive with a hex driver. Suitable for applications where the screw head will be exposed and the appearance is not a primary concern.

Material and Coating

Blue Climaseal®: The standard coating for Tapcon screws, offering excellent corrosion resistance. Suitable for most indoor and outdoor applications.

Stainless Steel: Provides superior corrosion resistance, making it ideal for harsh environments and applications exposed to moisture, such as outdoor projects or areas with high humidity.

4. Installation Tips

Drilling the Pilot Hole

Drill Bit Size: Use the appropriate size Tapcon drill bit for the screw diameter. For 3/16-inch screws, use a 5/32-inch drill bit. For 1/4-inch screws, use a 3/16-inch drill bit.

Depth: Drill the pilot hole at least 1/4 inch deeper than the length of the screw to allow for dust accumulation during installation.

Driving the Screw

Tool: Use a hammer drill for drilling the pilot hole and a standard drill or impact driver for driving the screw.

Speed: Drive the screw at a low to medium speed to avoid overheating and damaging the screw or the material.

See also: Impact Drill Vs. Hammer Drill: Understanding The Key Differences

5. Common Applications

Securing Wood to Concrete

Size Recommendation: 3/16-inch diameter screws with a length of at least 2 1/4 inches.

Type: Flat head screws for a flush finish.

Mounting Metal Fixtures

Size Recommendation: 1/4-inch diameter screws for heavier fixtures.

Type: Hex head screws for increased holding power.

Attaching Electrical Boxes

Size Recommendation: 3/16-inch diameter screws with a length of 1 3/4 inches.

Type: Flat head screws for a neat appearance.

Conclusion

Choosing the right Tapcon screws for your project involves considering the diameter, length, head style, and material of the screws. By understanding the specific requirements of your application and following the recommended installation practices, you can ensure a secure and durable fastening solution. Tapcon screws provide an efficient and reliable method for anchoring objects to masonry surfaces, making them an indispensable tool for both professionals and DIY enthusiasts.

Related Topics: