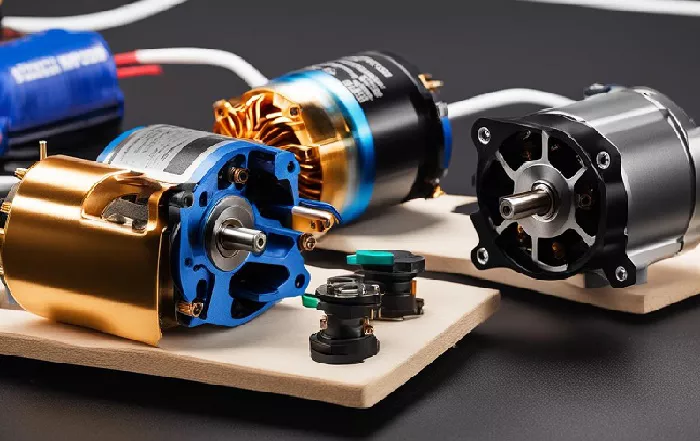

When it comes to selecting motors for various applications, understanding the fundamental differences between brush and brushless motors is crucial. Both types have distinct advantages and drawbacks depending on their intended use, and the choice between them can significantly impact performance, maintenance, and cost. This article will explore these differences in detail, providing you with a well-reasoned and thorough evaluation of brush and brushless motors.

What Are Brush Motors?

A brush motor, also known as a brushed DC motor, uses brushes and a commutator to transfer electrical current to the rotating armature. The core components of a brushed motor include:

Brushes: These are typically made of carbon or graphite and serve to deliver electrical current to the armature.

Commutator: A rotating switch that reverses the direction of current flow through the armature windings.

Armature: The rotating part of the motor that generates a magnetic field in response to the current from the brushes.

Brushed motors have been in use for over a century, powering everything from household appliances to industrial machinery. However, their design, while simple, introduces certain inefficiencies that modern technology has improved upon with brushless motors.

What Are Brushless Motors?

A brushless motor eliminates the use of brushes and commutators. Instead, it relies on permanent magnets in the rotor and an electronic controller to manage the flow of current through the windings in the stator. In brushless DC (BLDC) motors, the controller adjusts the phase of the current supplied to the stator to maintain rotation. The core components of a brushless motor include:

Permanent Magnets: Located in the rotor, these create a magnetic field that interacts with the stator.

Stator: The stationary part of the motor that contains the windings. When energized, the stator creates a rotating magnetic field that causes the rotor to spin.

Electronic Controller: A sophisticated system that replaces the mechanical commutator. It directs current to the appropriate windings of the stator at the right time to keep the rotor spinning smoothly.

Brushless motors are commonly used in high-performance applications such as drones, electric vehicles, and robotics, where efficiency, precision, and longevity are critical.

Key Differences Between Brush and Brushless Motors

While both motor types are used for similar applications, the key differences between brush and brushless motors can help you determine which one is better suited for your needs.

1. Efficiency

Brushless motors are generally more efficient than brushed motors. The absence of brushes reduces energy loss due to friction, allowing for higher efficiency and less heat generation. This efficiency is especially important in applications where battery life or power consumption is critical, such as electric vehicles or portable electronics.

In brushed motors, the friction between the brushes and the commutator creates energy loss, leading to reduced efficiency. Over time, this friction can cause wear on the brushes, further decreasing efficiency.

Verdict: Brushless motors offer better efficiency, which translates to longer operational times and reduced energy consumption.

2. Maintenance Requirements

Brushed motors require more frequent maintenance due to the wear and tear of the brushes. As the brushes rub against the commutator, they gradually wear down, which means they must be replaced periodically. In addition, the commutator can accumulate dirt or wear out, further complicating maintenance.

On the other hand, brushless motors have a significant advantage in terms of maintenance. Without brushes, there is less friction and no need for regular replacement of components. The primary maintenance concern for brushless motors is the electronic controller, but this typically lasts much longer than the brushes and commutator in brushed motors.

Verdict: Brushless motors require less maintenance and have a longer lifespan, making them more convenient and cost-effective over time.

3. Durability and Lifespan

Because brushed motors have moving parts that are in constant contact, such as brushes and the commutator, they are more prone to wear and tear. Over time, the friction generated by the brushes can lead to degradation of the motor’s performance. The average lifespan of a brushed motor is typically shorter than that of a brushless motor.

In contrast, brushless motors tend to last much longer due to the lack of physical contact between moving parts. The absence of brushes means there is significantly less wear, which contributes to the longer lifespan and greater reliability of brushless motors.

Verdict: Brushless motors generally have a longer lifespan and are more durable than brushed motors.

4. Size and Weight

Brushless motors are typically smaller and lighter than brushed motors with similar power ratings. This is because the design of a brushless motor is more efficient, allowing for smaller components without sacrificing performance. This makes brushless motors ideal for applications where space and weight are limited, such as drones, RC cars, and portable power tools.

In contrast, brushed motors are generally larger and heavier due to the need for a commutator and brushes. While this isn’t a significant issue in many industrial applications, it can be a drawback in smaller, portable devices.

Verdict: Brushless motors are lighter and more compact, making them suitable for applications where space and weight are crucial.

5. Control and Precision

Brushless motors offer superior control and precision due to their electronic controllers. These controllers can adjust the speed, torque, and direction of the motor with high precision, enabling smoother and more efficient operation. This level of control is essential in applications that require fine-tuned performance, such as robotics and advanced automotive systems.

In brushed motors, the speed and torque are controlled by varying the input voltage or current, but this process is less precise. While brushed motors are adequate for simple tasks, they cannot match the level of control offered by brushless motors.

Verdict: Brushless motors provide better control, making them ideal for applications requiring precise adjustments in speed and torque.

6. Cost

Brushed motors are generally more affordable than brushless motors. The simpler design and construction of brushed motors make them less expensive to manufacture. For applications that don’t require the high performance or longevity of a brushless motor, a brushed motor may be a cost-effective choice.

Brushless motors, due to their more complex design and the need for an electronic controller, tend to be more expensive. The additional cost of the controller and the advanced components can make brushless motors more expensive initially.

Verdict: Brushed motors are less expensive, making them a better option for budget-conscious projects where performance requirements are moderate.

7. Noise and Vibration

Brushless motors typically operate with less noise and vibration compared to brushed motors. The absence of brushes reduces friction and results in quieter operation. This is a key advantage in applications where noise is a concern, such as in audio equipment or medical devices.

Brushed motors generate more noise due to the friction between the brushes and the commutator. This can be problematic in environments where quiet operation is necessary.

Verdict: Brushless motors produce less noise and vibration, making them better suited for noise-sensitive applications.

Applications of Brush and Brushless Motors

Both brush and brushless motors have distinct advantages depending on the application.

Brush Motors: These are still widely used in applications where cost is a primary consideration and the motor does not need to run continuously for long periods. Common uses include power tools, household appliances, and older automotive applications.

Brushless Motors: These are favored in high-performance, energy-efficient applications that demand longer lifespans and precise control. They are commonly found in modern electric vehicles, drones, robotics, HVAC systems, and advanced industrial machinery.

Conclusion

Choosing between a brush and a brushless motor depends on the specific needs of your application. Brushless motors offer greater efficiency, durability, control, and quieter operation, making them the ideal choice for high-performance, long-lasting, and energy-efficient solutions. However, they come at a higher initial cost.

Brushed motors, while more affordable, tend to be less efficient, require more maintenance, and have a shorter lifespan. They may still be a good choice for budget-sensitive projects where the motor is not expected to run for long periods or under heavy load.

By carefully evaluating the trade-offs between these two types of motors, you can make an informed decision that optimizes both performance and cost-effectiveness for your specific needs.

Related topics:

- Ridgid Table Saw: A Comprehensive And Objective Evaluation

- Ryobi Inverter Generator Review: Performance, Features, And Value

- Ryobi Cordless Sander Review: A Comprehensive And Objective Evaluation