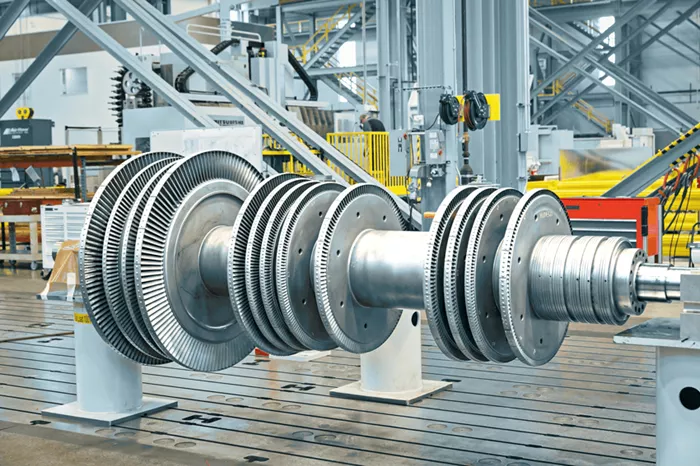

Mitsubishi Heavy Industries Compressor International Corporation (MCO-I), a leader in the design and manufacturing of compressors, steam turbines, and associated auxiliaries, has revolutionized steam turbine maintenance by incorporating Phased Array Ultrasonic Testing (PAUT) technology.

This breakthrough technology is a game-changer in ensuring sustained efficiency and safety within the energy sector, where the endurance and dependability of steam turbines are paramount. Traditionally, inspecting steam turbine rotors for defects could be challenging due to the limitations of conventional methods. PAUT offers an unparalleled level of accuracy in detecting minuscule cracks in steam turbine rotors that would otherwise go unnoticed.

Initially developed for medical applications, MCO-I has adapted PAUT to the industrial realm, allowing plant operators to access real-time insights for more informed decisions about maintenance schedules. This leads to optimized turbine performance and a longer operational life for the equipment.

Justin Fleming, Customer Service Business Director at MCO-I, shared, “Incorporating PAUT into our steam turbine maintenance is a huge step for us. This technology not only boosts our ability to provide value to our customers through advanced inspection techniques but also gives our clients real data to make better decisions on maintaining their equipment longer and more reliably.”

PAUT inspections are available to all MCO-I clients as an enhancement to their service package. The company recommends these inspections for turbines with a service life of 10 years or more, with MCO-I offering maintenance for any OEM rotor, as long as clients provide key details such as the size, location, environment, and original geometry of the machine.

As steam turbine technology evolves, MCO-I remains at the cutting edge, continually redefining industry standards. The integration of PAUT marks a pivotal moment in the ongoing pursuit of enhanced efficiency, safety, and longevity in energy production.

Related topics:

- Hitachi Supports ARA Foundation with Donation of Custom Air Compressor

- Texas Eastern Pipeline Seeks Changes to Compressor Station Upgrade Plans

- BITZER UK Launches One-Day Training on Advanced Compressor Technology